Curbing Fuel Wastage in Mining with AI

Curbing Fuel Wastage in Mining with AI

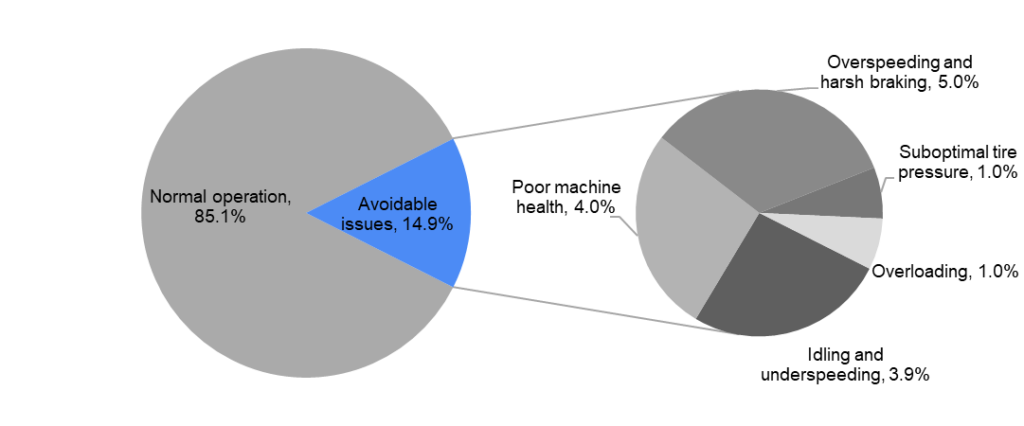

Fuel efficiency is a key operational factor in the mining industry, significantly influencing costs and ESG standing of the mining companies. Still, fuel wastage remains a serious issue, primarily due to operational and behavioral inefficiencies, including idling, poor machine health, speeding, harsh breaking, suboptimal tire pressure, and overloading. To understand how prevent fuel wastage, our team has analyzed fuel consumption data across various sites and conducted comprehensive research to identify operational inefficiencies that burn unnecessary fuel. Based on our findings, up to 14.9% of the fuel on a typical mine site is being wasted.

The fuel wastage is being addressed by various tactics, including:

- Driver training and awareness. By educating machine operators about the impact of their driving habits on fuel consumption, wastage can be significantly reduced. According to Fleet Equipment Magazine, drivers can affect vehicle fuel economy by as much as 35%.

- Regular maintenance. Consistent and regular maintenance of equipment can ensure vehicles are operating at their peak efficiency. Based on the Alternative Fuels Data Center at the U.S. Department of Energy data, tuning a neglected vehicle can increase fuel economy by an average of 4%.

- Strategic Scheduling and Route Planning. Efficient planning of operations can minimize unnecessary vehicle movement, and consequently reduce fuel consumption.

Undoubtedly, driving improvements across diverse areas – operational efficiency, safety, and environmental sustainability – could appear as a daunting task. It might seem akin to chasing multiple elusive rabbits simultaneously. However, in this plurality of objectives, AI technology emerges as a powerful ally.

AI Targeting Non-Productive Idling

Not all idling negatively impacts productivity. Much of the idling time is ‘productive,’ such as when machinery is kept running during the loading cycles. However, a percentage of idling is ‘non-productive’ and preventable. AI-powered solutions analyze equipment data, detecting the patterns of non-productive idling and triggering alerts to control room operators so that they can curtail needless fuel burn.

AI Improving Machine Health

Here, AI steps in with predictive maintenance strategies. By analyzing machine data, describing factors such as fuel or air filter health, AI algorithms identify potential failures, enabling predictive maintenance to enhance efficiency and conserve fuel. Cumulative impact of predictive maintenance on fuel economy is up to 10%, according to a report from North American Council for Freight Efficiency.

AI Detecting Speeding and Harsh Braking

AI-powered solutions can monitor driving habits in real-time, detecting inefficiencies and providing operator feedback to modify driving habits, subsequently reducing fuel usage.

AI Controlling Tire Pressure

Underinflated tires degrade fuel efficiency and accelerate tire wear. AI algorithms can leverage the data from tire pressure monitoring sensors (TPMS), dispatching real-time alerts when adjustments are needed to maintain optimal fuel efficiency.

AI Preventing Trucks’ Overloading

Overloading equipment escalates fuel consumption. By constantly monitoring and managing equipment load, AI-based products can assure operations remain within optimal ranges for fuel efficiency.

In essence, AI’s capacity to analyze massive data volumes in real-time and predict future patterns makes it a formidable tool for combating fuel wastage in mining. As we continue to refine our AI-powered solutions, we foresee a transformative impact on fuel consumption and the wider mining industry.

Interested in learning more about how AI can transform your operations for better fuel efficiency and sustainability? We invite you to reach out to us. Let’s explore how we can work together towards a more efficient and sustainable future of your mining fleet.