SymBotic Relationship

SymBotic Relationship

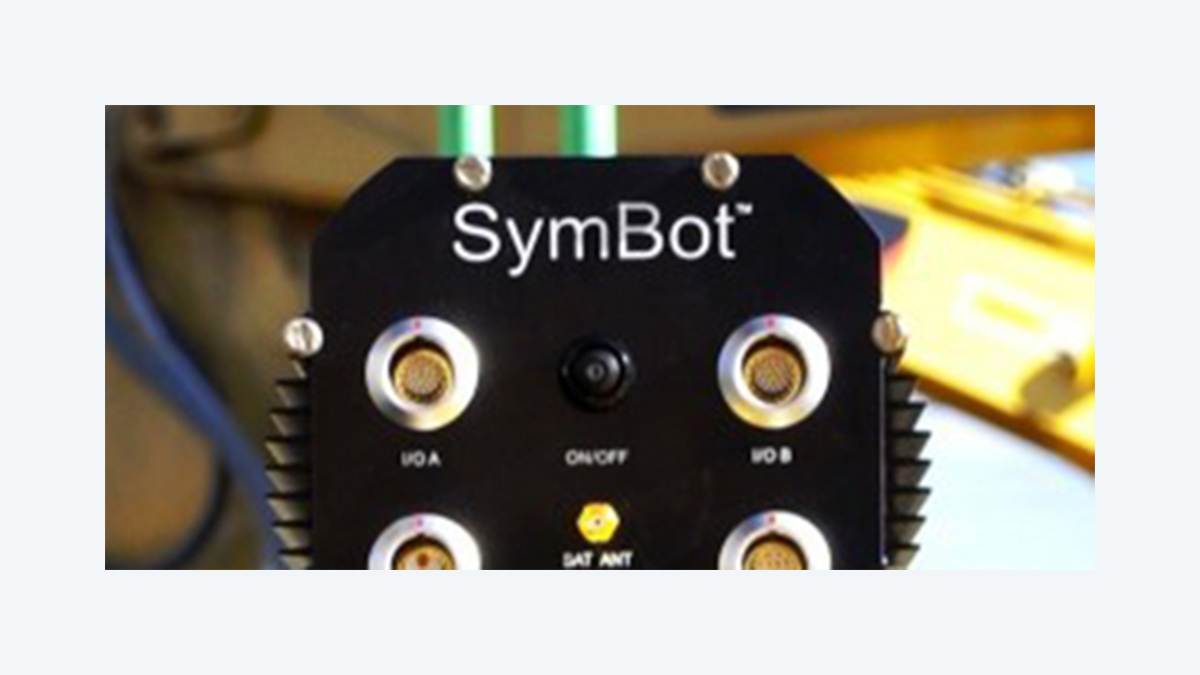

In the complex, harsh world of mining, the SymBot, a new equipment monitoring platform that communicates by satellite, cellular network and Wi-Fi, is built tough and, as the name suggests, SymBot plays well with others.

The SymBot platform, designed to comply with open standards for industrial automation and systems interoperability, is a durable, energy-efficient hardware/software device that can be applied to monitor equipment information such as location, pay load data and emissions or operating environments.

The device hails back to 2008 when its parent company, Symboticware, received grants from the Ontario and federal governments to develop what was an R&D project into a full-fledged commercial product.

Above ground, a partnership was formed between Symboticware, junior mining firm Baffinland Iron Mines, the Centre for Excellence in Mining Innovation (CEMI) and Laurentian University. The project centred on a weather monitoring system on north Baffin Island. The challenge was not just extreme weather; the company’s co-founder and president, Kirk Petroski, explains that the monitoring stations are accessible by helicopter only, which makes in-person site visits difficult, costly, and subject to the vagaries of the local weather.

HANDS ON/HANDS FREE

To make site visits as infrequent as possible, Symboticware managed to cut power consumption on the SymBots down to as little as 10W, and used solar panels to keep the batteries topped up, making the unit almost completely self-sufficient. Also, SymBots’ satellite uplink means that the customers no longer have to visit the station to retrieve the collected data. But most important is that the satellite connection provides two-way communications and the SymBots’ operational parameters can be remotely controlled.

“SymBots allow the researchers or industry personnel to check the status and conditions around the station in real time and to change the parameters as needed,” explains Symboticware’s marketing and sales manager Bora Ugurgel. “So, if you’re sampling every five seconds, you can change that to every two hours in the winter months.”

The utility of up-to-the-minute information provided by these weather stations is clear, says Baffinland Iron Mines’ manager of sustainable development Matthew Pickard. “The data is important to us because it can tell us if we are expecting weather up there, but it can also be useful from the operational side. We have proposed mine infrastructure across a 250 kilometre strike width, so you don’t want a helicopter taking off and then turning around and coming back because it ran into bad weather. That can amount to thousands of dollars in costs to no useful end. Once we confirm the SymBots can work independently in the long, dark, cold winters of North Baffin Island, we hope to expand their use into other remote monitoring functions such as water quality monitoring.”

The Baffin Island project — which has since expanded to include Peregrine Diamonds, another advanced-stage exploration company — is going to be revisited this summer with a second phase. This time, Symboticware will be introducing a hybrid solar-wind power generation system to keep the SymBots charged up, but the software side will also see enhancements.

“We’re trying to reduce costs for our customers,” says Ugurgel. “Satellite data transmission costs are about $2 per kilobyte. With our in-house data compression system, we’d be able to compress the data by 70 to 80 per cent, significantly reducing airtime costs.”

In its underground projects, Symboticware sought out what Petroski describes as early adopters — mines in which a wireless communications infrastructure has been set up.

“The timing was paramount to the success of where we are today,” he adds. “Given that there was a decline in the economy and mining really took a hit, there was a period when a lot of the automation guys, for example the automation superintendent at Vale Inco, were looking for ways to do business better and to bring in a lot of new technologies.”

The SymBots are currently being used by both Vale Inco and Xstrata Nickel to monitor mobile equipment — most notably the two companies’ load-haul-dump (LHD) vehicles. Since the SymBots can draw power directly from the LHD machines they are monitoring, power management is not as much of an issue in this context, says Petroski. On the other hand, connectivity and constant vibration were a concern. There were also more direct threats to effective operation — being hit by large rocks, for instance.

“When you’re placing the SymBot on an LHD, you have to look in hard spots to keep your sensors safe and lasting as long as you can,” explains Ugurgel.

ENHANCED INFORMATION EXCHANGE

The need for mobile equipment monitoring is not new, and Symboticware had to contend with a wide range of existing solutions and devices already in place, which, in fact, was an advantage for the SymBot. As operator needs for data collection grew over the years, so did the number of specialized solutions in the driver’s cab — each with its own display, control system, and proprietary data standard. The growing trend for crowded cabs led to a push for open standards — common data formats that would allow for greater interoperability between all the disparate systems. When Symboticware approached them, both Vale Inco and Xstrata were already moving towards greater use of IREDES — the International Rock Excavation Data Exchange Standard designed to smooth the transfer of information between mining machines and office computers. It is no coincidence that the SymBots supported IREDES, along with OPC UA — a complementary, communication interface.

The idea is not to replace existing, proprietary systems, says Petroski, but to step in where these systems have gaps. Two projects currently being worked on at Symboticware are being demonstrated on Caterpillar 1700G LHD machines, “based on Caterpillar’s proprietary data system,” says Petroski. “In the context of these projects, we’re developing a protocol translator — taking Caterpillar data, running it through a translator and pushing it up to the surface in the format that the clients wanted; in this case an IREDES-based format.”

AN OPEN-PLATFORM SOLUTION

Look inside the SymBot enclosure and you are not going to see much in the way of custom parts. Symboticware tries to use as many commercial off-the-shelf parts as it can, says Petroski. In a marked contrast to the proprietary trend, Symboticware’s software OPIS(TM) (Open Platform for Intelligent Systems) facilitates an open platform environment, meaning anyone with the skill and desire can alter the programming, or write their own application for the platform.

This was the factor that compelled CEMI to partner with Symboticware, explains Allan Akerman CEMI’s R&D program director: “With closed systems you are tied in with one supplier; with open systems you can use the best of any supplier.” Added to that, he says there is also a cost advantage to meeting the single IREDES requirements rather than multiple standards. “The majority of mining equipment manufacturers are now on board with IREDES,” he says, and more and more mining companies are committing to the single standard as well.

“If I could use the analogy, we’ve developed the iPhone for the mining industry, and you’re loading applications onto this device,” says Petroski. “The money is in the applications. So we’re developing our own applications, but we’re also integrating third-party applications into our system and providing that to our users as per their needs.”

With five SymBots operating “in the wild” and 16 already on order for this summer’s projects, Symboticware is still a young, but clearly growing, company. Petroski says he expects the company’s eight-person roster to grow to 12 within a year, mostly adding technical sales and support staff. Capitalizing on the platform’s flexibility, the company has a number of new applications planned for the SymBot, ranging from an open WiFi-RFID (radio-frequency identification) reader and tracking system to a portable environmental monitoring station, which can be moved from spot to spot as needed, without requiring costly installation of fixed equipment.

For the time being, Symboticware is not looking to expand into other industries, although Petroski readily acknowledges that there are many other promising areas for the SymBot. “We want to succeed and excel in these two markets before we tackle others,” he says

Via CIM Magazine by D. Zlotnikov