Symboticware’s 3 Steps To Turn Data Into Value

Symboticware’s 3 Steps To Turn Data Into Value

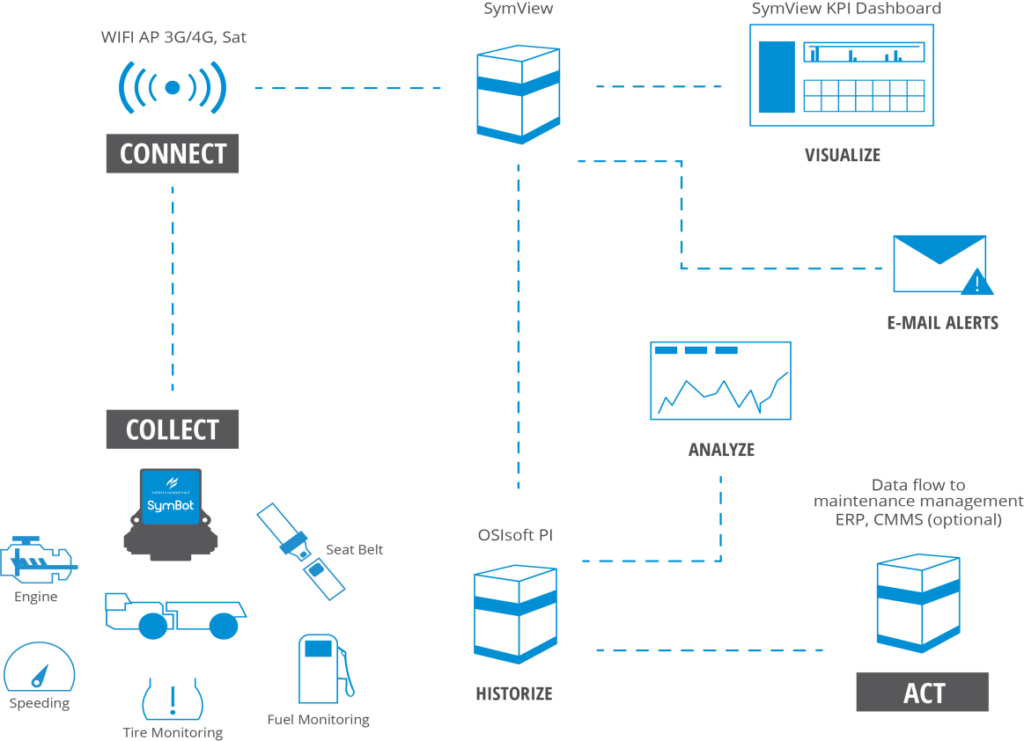

Symboticware is a global technology provider of purpose-built data acquisition solutions focused on heavy industrial applications. Our telemetry solution consists of two key components: the SymBot device and our SymView software. The SymBot is an industrial data acquisition solution for the collection, aggregation and delivery of vehicle data. SymView is our data aggregator, analytics suite, SymBot management tool, and integration point for additional systems for enhanced analytics in the system of your choosing.

Collect

The first stage of any telemetry solution is the gathering of data from all relevant sources of interest. For this task, Symboticware employs its SymBot product. The SymBot is our data collection hub, and is our physical connection point to the mobile asset that we wish to collect data from and all of its installed peripherals.

Connect

The next step is to take all of the consolidated data and deliver it to a system accessible for analysis so that action can be taken. The SymBots have the capacity to connect through a mine’s existing WiFi access points, through LTE 3G/4G, or, in very remote applications, through satellite. Once this connection is established the data is delivered to our central data aggregator: SymView.

SymView provides the ability to visualize raw data and present KPIs in a web-based dashboard, generate email alerts based on these KPIs, and integrate with data historians and other solutions for historization and deep analytics of the data with machine learning and artificial intelligence algorithms.

Act

The final, and most important stage, it is now time to take action with the data. Delivery of data to the maintenance department’s ERP and CMMS for quicker, better resource planning and utilization. Integration with business operations suites to save time in generating work orders and planning shifts. There are numerous opportunities to take action with data, and to bring value to the organization by improving efficiency and giving the company a competitive advantage.

All Together

Below the full process described above is visualized: the SymBot gathers the data from the mobile asset and its suite of sensors, it connects to deliver the data to SymView, SymView directs the data to where it is needed, and action is then driven based on this data to generate value.

| Symbot | Symview |

|---|---|

| The SymBot interfaces to the vehicle onboard sensor networks using OEM supplied interfaces and installed peripherals; it collects and time stamps data parameters from haul trucks, loaders, other mining production and support vehicles. | SymView acts as the receiving node of the collected sensor/vehicle data. It is our analytics and integration tool. It enables condition-based maintenance schemes, criticality analysis, failure mode analysis, and the review of performance metrics. |

Bringing Value to Your Data

Our KPI software has several configurable KPIs to monitor critical vehicle health components that could bring the vehicle out of production and assists in identifying opportunities for preventative maintenance before a major, and costly, failure occurs. Popular KPIs include:

| Vehicle Health | Operator Safety | Productivity |

|---|---|---|

| Oil Pressure monitoring TPMS monitoring Transmission and Engine Temperatures | Seatbelt usage/compliance Transmission abuse Overspeed detection and over-revving of engines | Identification high idle times Load weight estimation Cycle times |

Our Integrations

Symboticware can integrate with a number of data sources and data reporting solutions. Here are just some of the options available:

| Symbot | Symview |

|---|---|

| CDL, J1939, J1708, VIMS, TPMS systems, load cell systems, RFID tag readers, GPS, and more. | OSIsoft PI, SAP, ERP, CMMS, industrial artificial intelligence solutions, and more. |

The Future of Symboticware Telemetry

Plans for future iterations of SymView will target migrating to Cloud based architecture, allowing us to enhance and expand on the business value applied to the data collected. This will bring in new features such as machine learning to detect performance deviation/deterioration between vehicles, data projections to identify potential vehicle health problems before they occur, and vast expansions to business reporting, event analytics, and user driven data science.